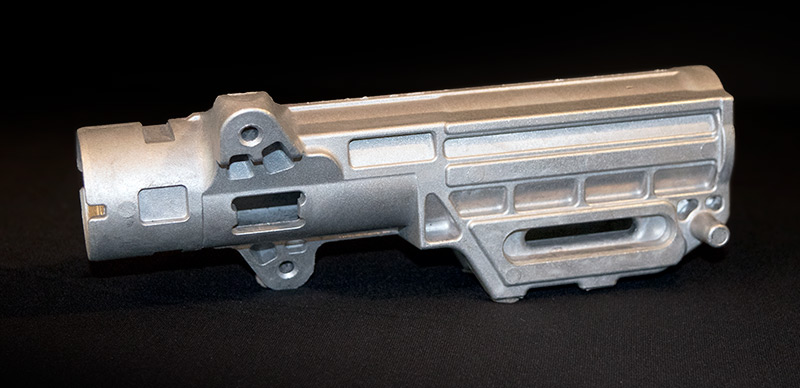

JMMS Tooling for

Automotive OEMs and Tier Vendors

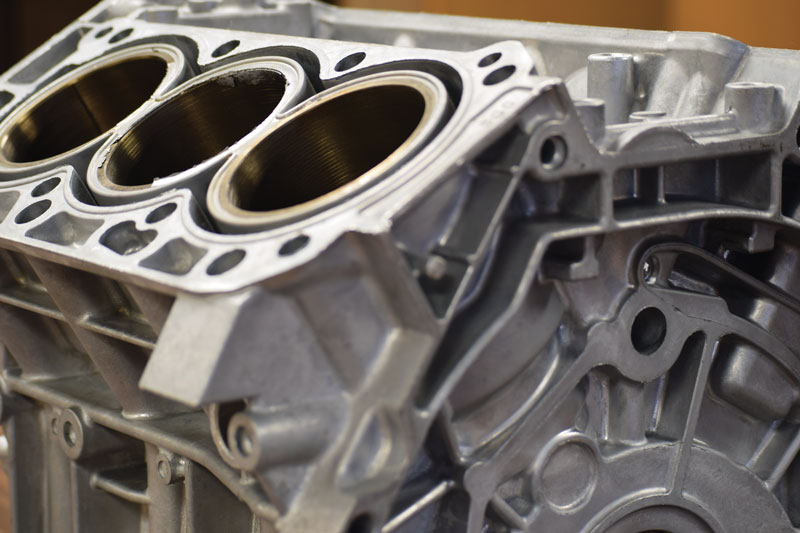

We’re a Tier One and Tier Two vendor for automotive OEMs, working directly with OEM tooling engineers and their Tier base. We offer total program management for both injection molding and die casting, developing tooling that meets OEM quality benchmarks, add capacity and reduce costs.

Our total program management begins with an assessment of your parts, materials and volume requirements, working with your production engineers or as part of a single-source solution.

Proven part and tooling optimization

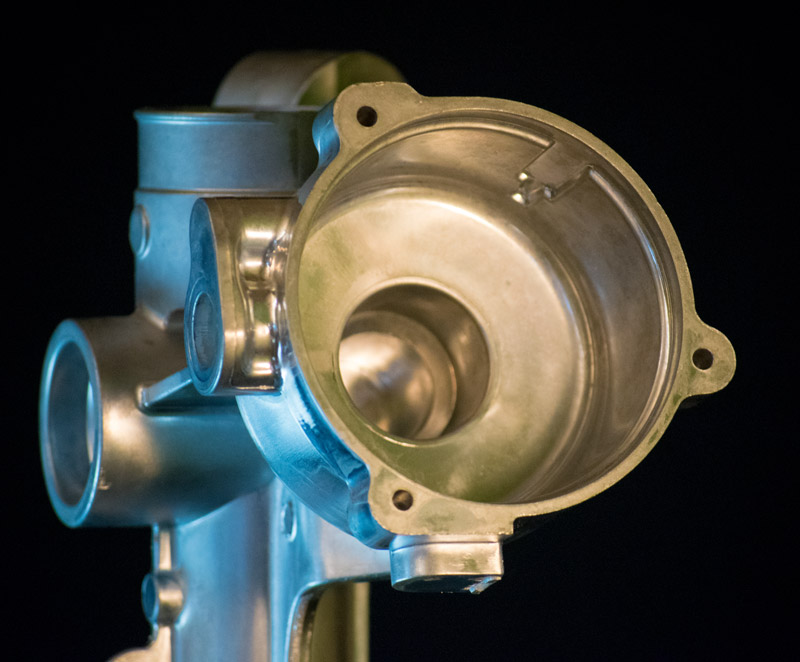

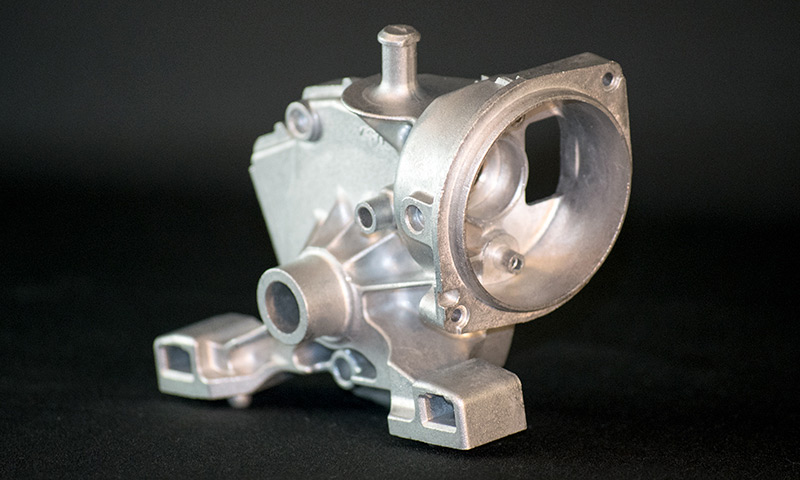

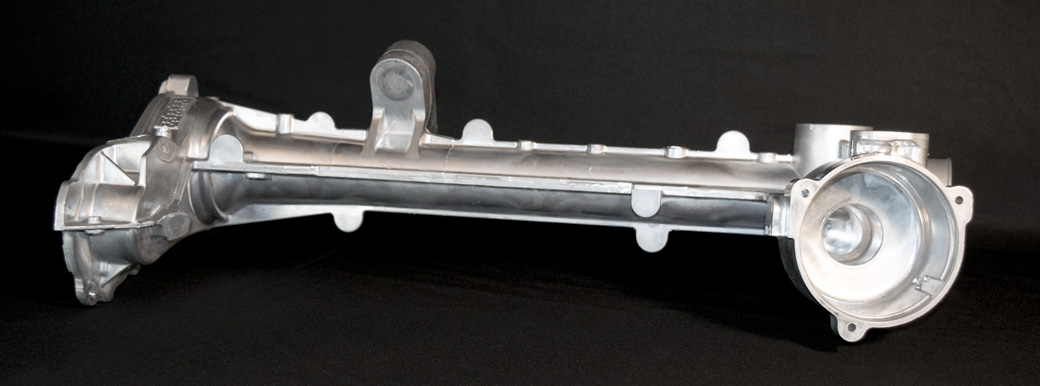

We specialize in tooling for engine components, interior trim and seat trim components. Our experience includes both part optimization and mold or die optimization — we can help you improve part quality and dimensional stability, while reducing material usage and cycle times.

JMMS engineers will work side by side with you on-site, reviewing tryout data and optimizing your molds and dies. We have extensive experience with cooling channel design, as well as engineering interchangeable, multi-cavity inserts and components.

Lower cycle times for thermoplastic injection molding

Today, OEMs are more focused on strategic tooling investments, pushing their Tier base to cut cycle times and add capacity. We provide troubleshooting for our OEMs’ thermoplastics vendors, working with engineered alloys to build hybrid tooling that offers faster cooling and lower cycle times than molds built with tool-grade steels.

You can read more about our work on hybrid tooling here (links to “The Forecast Called for Aluminum.”)

OEM quality with a lower total cost of ownership

Our primary objective with automotive tooling is to meet OEM quality benchmarks while optimizing your manufacturing process and lowering your total cost of ownership. This process includes:

- Design and development

- Prototype to production tool quantities

- Design maturation and optimization

- Operation

- Maintenance and repair

We deliver total program management for automotive OEMs and their Tier vendors, focusing on die casting and thermoplastic injection molding.

Serving the Southeast and beyond

JMMS operations in Easley, SC position us for fast on-site service and lower shipping costs for Southeastern manufacturers, but we also build and ship tooling coast to coast.

Our dedicated maintenance team delivers preventive maintenance, repairs and molds to all your tooling (ours and other suppliers’).

A solution provider for thermoplastic issues in the Tier base

We solve problems with thermoplastic injection molding for automotive OEMs and their Tier suppliers — contact David Bowers II at 864.855.0450 or email for solution to your parts quality or production problems.

Total program management for

Die Casting and Metals Tooling

Total program management for

Plastic Injection Molding

Total program management for

Design and Engineering

To learn more about how JMMS can help you, call us at 864.855.0450 or email.