JMMS Injection Mold Design and Engineering

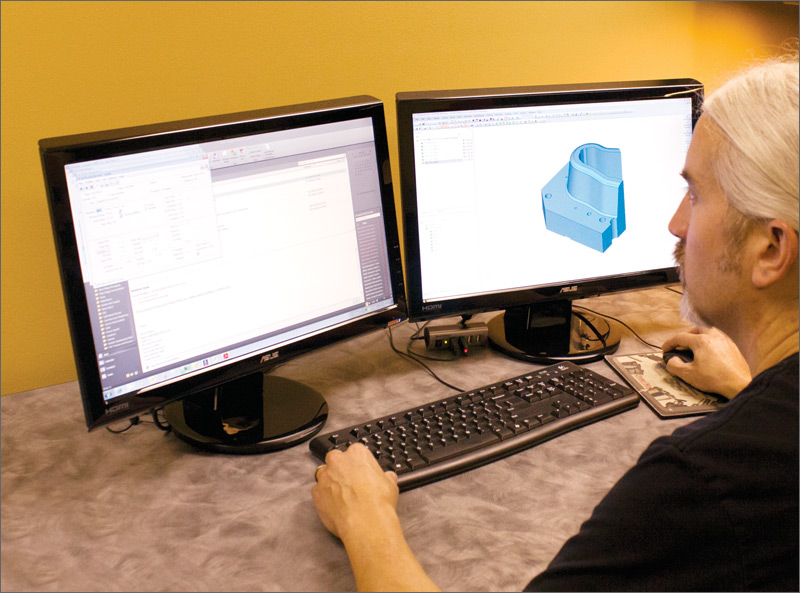

JMMS can optimize your part and injection mold design to increase output without re-engineering production lines. Our production optimization includes part design, mold design, mold materials and injection molding conditions/parameters.

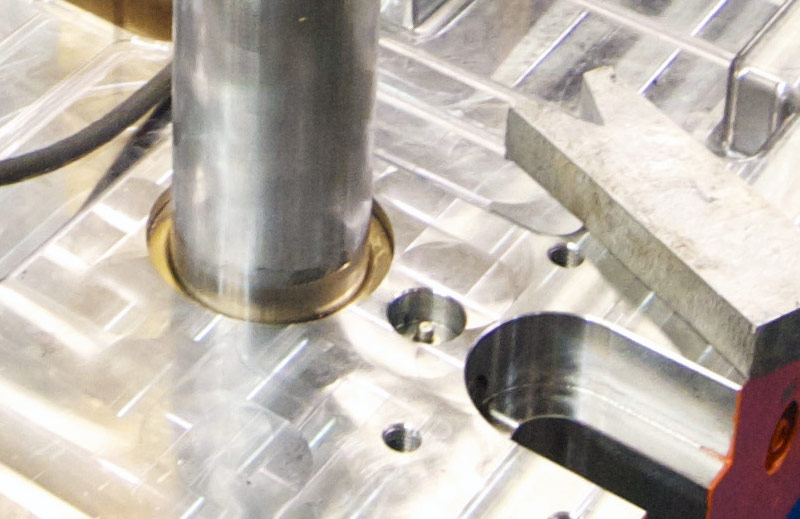

We also engineer mold flow and cooling, add Cavity Pressure Transducers (CPTs) where appropriate, and use alloys that reduce cycle times.

Proven injection molding troubleshooting

Our engineers and tool makers have a track record in working with global OEMs and their thermoplastic base to resolve part quality and production problems. These include:

- Voids, sinks and bubbles

- Flash

- Non-fill

- Flow marks

- Back fill

- Ejector pin marks

- Surface defects

- Color variation

Using design for manufacturability principles and our experience with the variables of injection molding, such as injection pressure, cavity pressure, cooling time and cycle time, we can help you optimize both your parts and production.

JMMS production optimization includes part and die design.

Increase production volumes 20-30%

We work with alternative materials offering higher thermal conductivity and more strength than traditional tool steels (our molds made with these highly engineered alloys. These materials offer a 20-30% increase in production volumes, while improving dimensional stability, durability and corrosion resistance.

Tools built with our hybrid approach and alternative materials represent a larger initial investment, but accelerate the return on investment with high-volume production.

CPTs for more precise control of flow and delivery

We work closely with technology partners developing cavity pressure transducers to optimize production of low-pressure structural foam molding and high-pressure thermoset and thermoplastic molding. Monitoring temperature and pressure allow more precise control of flow and delivery, the key process variables driving complete mold fill-out.

To see the benefits of direct measurement and added control in a mold flow simulation, contact Jeramy Martin at 864.855.0450.Total program management for Injection Molding & Plastics Tooling:

To learn more about how JMMS can help you, call us at 864.855.0450 or email.