JMMS Extrusion Blow Molds

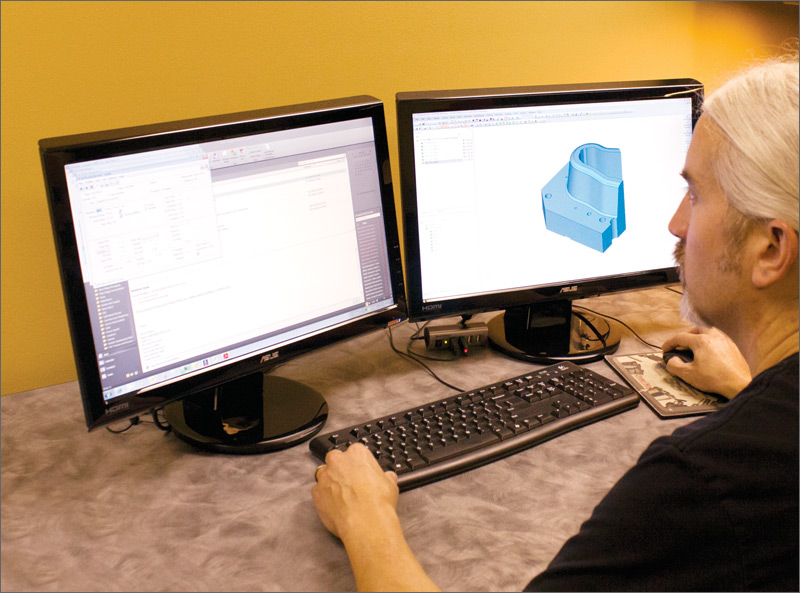

JMMS total program management for extrusion blow molds delivers the QA, cycle times and production quality you need, combining design and engineering, mold manufacturing and maintenance.

Our experience with blow molding includes working with POS and merchandising display companies, as well as automotive OEMs and Tier One suppliers (we engineer aluminum molds to produce airways and ductwork).

Rapid prototyping and concurrent engineering for faster development

We make blow molds to process various materials, including polyethylene and polypropylene. JMMS warranties these molds for appearance (design, workmanship and materials), cycle time and dimensional stability, as well as blow pressure to pick up surface detail in the mold and minimize thickness variations.

Our industry experience includes:

- Consumer products

- POS and merchandising displays

- Blow-molded coolers

- Child safety seats

- Automotive products

- Airways

- Ductwork

- Recreation/utility vehicles

- Gas tanks

JMMS has extensive experience in building extrusion blow molds, working with automotive OEMs and their Tier One suppliers.

Total program management for Injection Molding & Plastics Tooling:

To learn more about how JMMS can help you, call us at 864.855.0450 or email.