Part Design / Assistance

JMMS Part Design/Assistance for Die Casting and Injection Molding

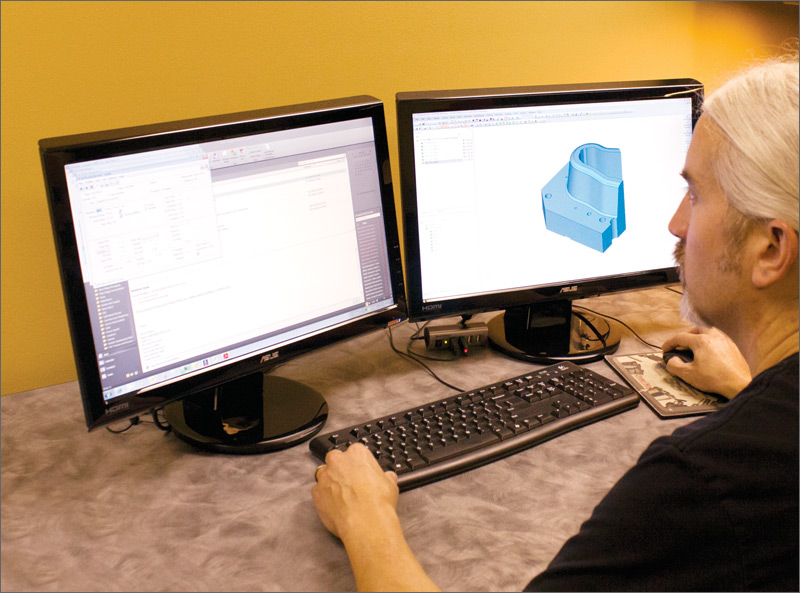

JMMS offers industrial design capabilities to support part design for both die casting and injection molding. We can reverse-engineer from legacy parts or a pencil sketch, building a 3D database to begin 3D design.

In addition to solid modeling and conversion of large data sets, we use finite element analysis and plastic part mold flow simulations. Our industry-specific experience guides the process, using APQP guidelines to design for manufacturability. As we share drawings, we can evaluate ways to improve quality and reduce material usage, which cuts weight, cycle times and cost.

The benefits of early involvement

Early involvement helps us improve both part quality and your production process. We conduct manufacturing feasibility evaluations and offer design improvements, such as reducing heavy wall sections.

Our cradle-to-grave Cimatron 13.0 platform supports collaboration and optimization. JMMS engineers have the industry-specific experience to help you meet OEM specifications for functionality, including material flow, parting line, gate location and ejector marks.

JMMS offers part design and assistance for both injection molding and die casting, with a focus on design for manufacturability.

The sweet spot — OEM spec at the lowest possible price

In the end, you want tooling to produce parts that meet OEM specifications at the lowest possible price. We work with global OEMs and their Tier base precisely because we know how to reconcile those two objectives.

JMMS tooling engineering includes:

To learn more about how JMMS can help you, call us at 864.855.0450 or email.