JMMS Tooling for

Consumer Products

JMMS has extensive experience with tooling for consumer products, engineering, manufacturing and maintaining thermoplastic injection molds and extrusion blow molds. We make tooling for:

- POS and merchandising displays

- Shelf bins

- Delivery trays

- Convenience store shelving

- Blow-molded coolers

- Child safety seats

Our total program management helps you solve or prevent part quality and production problems, beginning with an assessment of your parts, materials and volume requirements. JMMS engineers will work with your production engineers or as part of our single-source solution.

Tighter QA for a lower TCO

We focus on engineering and manufacturing molds that supports your QA, optimizing the manufacturing process to lower the total cost of ownership for your tooling. You need ISO-registered, documented compliance and we deliver, controlling every phase of your mold lifespan.

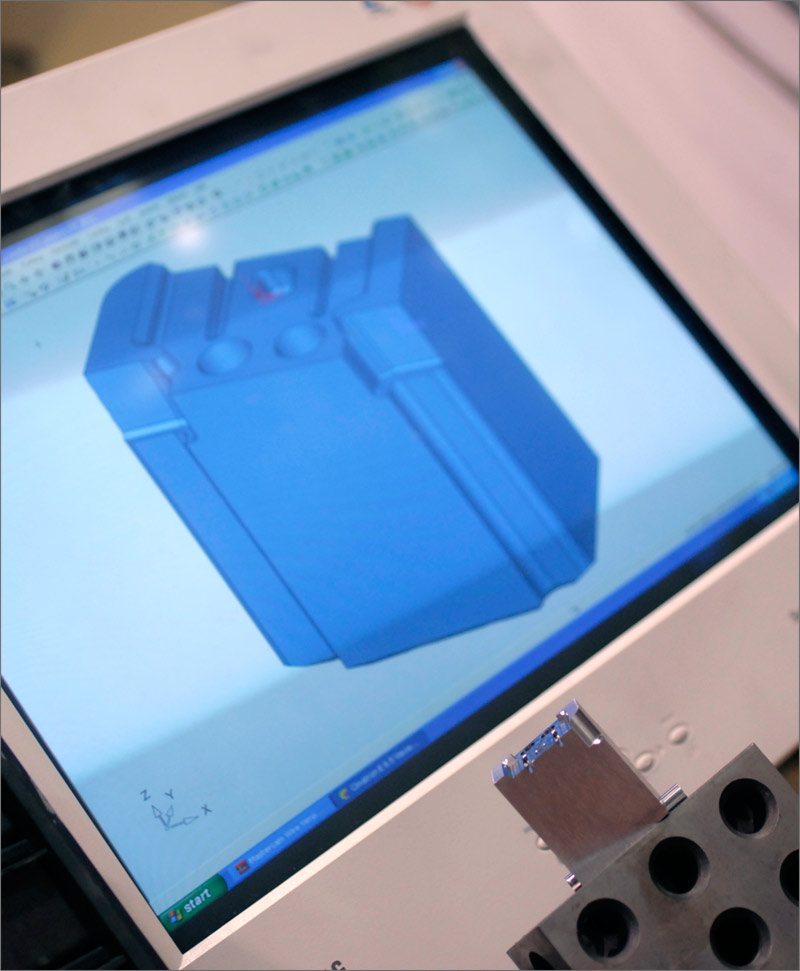

JMMS engineers will work side by side with you on site, reviewing tryout data and optimizing your molds to lower cycle times, reduce material usage and improve quality. Our Cimatron 13.0 platform integrates your production engineers with JMMS engineers in Easley, SC and Dong Guan, focusing more thinking on your problems and cost-effective solutions.

JMMS makes tooling for consumer products — POS and merchandising displays, shelf bins, delivery trays and convenience store shelving — with the experience you need with cooling channel design and engineering interchangeable inserts and components.

Single-source maintenance for your tooling — ours and from other suppliers.

Dedicated maintenance for all of your molds

Our headquarters in Easley, SC positions us for fast on-site service and lower freight costs for Southeastern manufacturers (we build and ship tooling coast to coast). The JMMS dedicated maintenance team supports Southeastern plants with preventive maintenance, repairs and modifications on molds and dies (JMMS and legacy tooling).

Total program management for

Die Casting and Metals Tooling

Total program management for

Plastic Injection Molding

Total program management for

Design and Engineering

To learn more about how JMMS can help you, call us at 864.855.0450 or email.