JMMS Tooling for

Medical Technologies

JMMS has years of experience in manufacturing tooling for medical technology OEMs, with a focus on plastic injection molding for medical devices and reaction injection molding. Our total program management meets OEM quality benchmarks while lowering your total cost of ownership.

We make tooling for:

- Molded components for dental chairs and lights

- Molded components for exam chairs

- Medical enclosures and cabinetry

- Bio chambers

- Dental tool holders

Faster RIM development and production

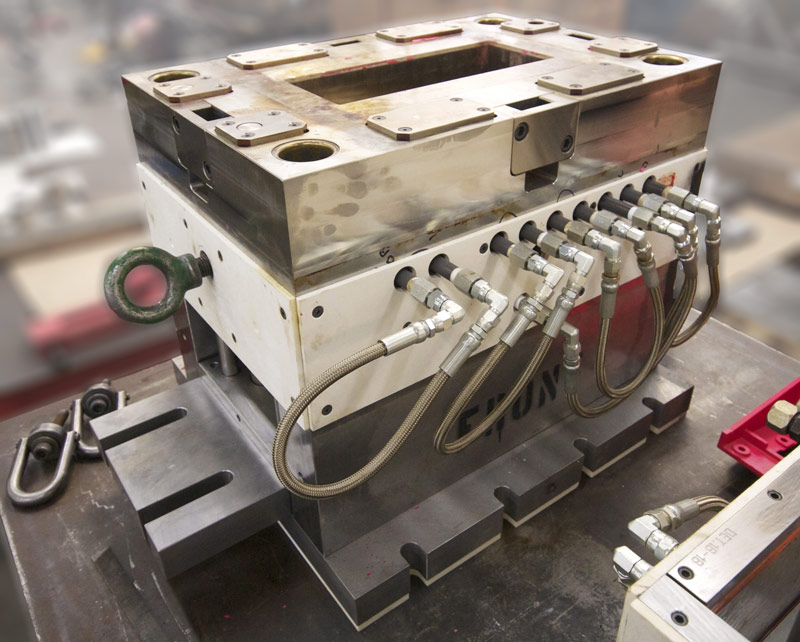

We specialize in tooling design and engineering for reaction injection molding (RIM). These molds are ideal for producing structural parts and enclosures in relatively low volumes and for a lower cost, as we can make these molds with aluminum instead of steel.

Our rapid prototyping and concurrent engineering accelerates maturation and optimization, which cuts our lead time for development and production (we usually deliver these molds in six weeks or less).

JMMS specializes in reaction injection molding for low-volume production of structural parts and enclosures.

Higher quality with less material and lower cycle times

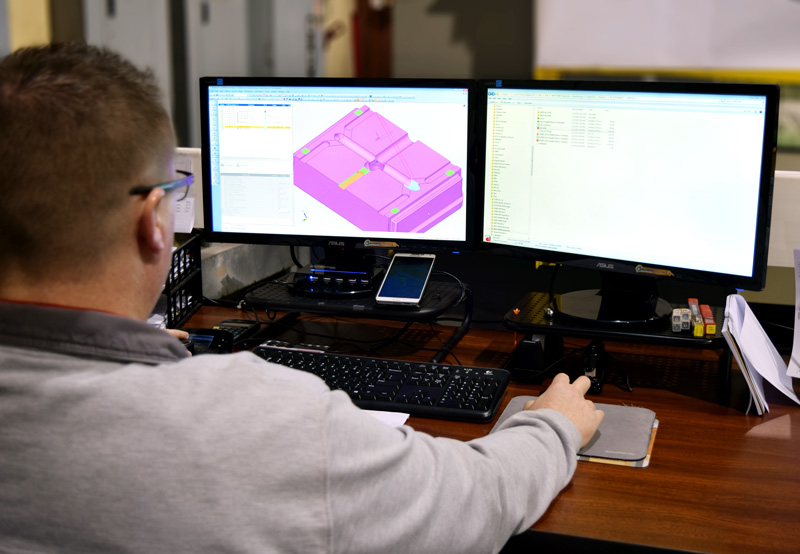

We work side by side with your engineers on site, reviewing tryout data to optimize for better QA, reduced material and faster cycles. Our ISO-registered, documented QA controls every phase of your mold lifespan:

- Design and development

- Prototype to production quantities

- Design maturation and optimization

- Operation

- Maintenance, repair and overhaul

Ongoing service and support in the Southeast

Our headquarters in Easley, SC position us for fast on-site service and lower freight costs for Southeastern manufacturers (we build and ship tooling coast to coast). JMMS dedicated maintenance and repair specialists provide the preventive maintenance your tooling requires, along with repairs and modifications for our tooling and other suppliers’.

Total program management for

Die Casting and Metals Tooling

Total program management for

Plastic Injection Molding

Total program management for

Design and Engineering

To learn more about how JMMS can help you, call us at 864.855.0450 or email.