JMMS Tooling for

Power Tool OEMs

JMMS has the industry experience power tool OEMs look for in their tooling suppliers. We specialize in total program management for injection molding, adding value at every point in the mold lifespan.

We manufacture injection molding for the production of these power tool components:

- Blade guards

- Drill noses

- Router housings

- Plastic housings and casings

- Housings and handle sets for hand tools

Meet your OEM quality and production benchmarks

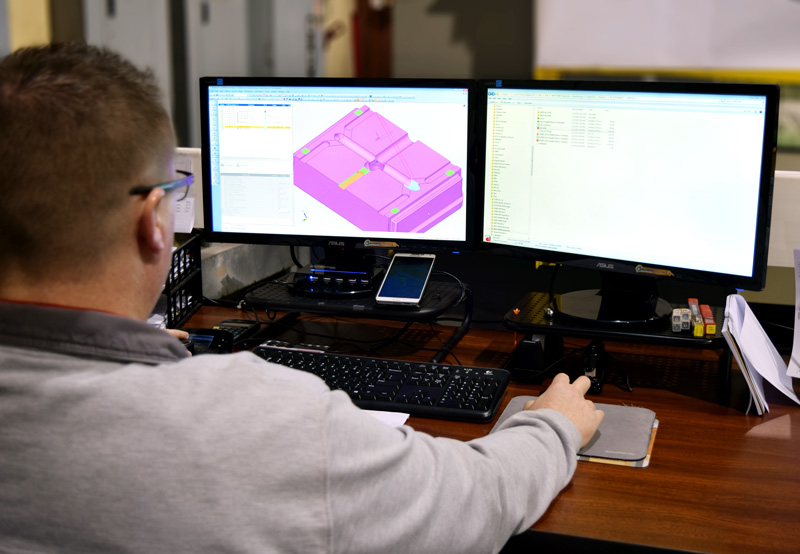

Our total program management begins with an assessment of your part design, material usage and volume requirements. JMMS engineers can work with your production engineers or as part of our single-source solution.

We specialize in meeting OEM quality and production benchmarks, reviewing tryout data and optimizing part and mold design for reduced material usage, lower cycle times and better part quality. We have a track record in solving injection molding problems, cutting cycle times with innovative cooling channel design and engineering interchangeable inserts and components.

JMMS provides power tooling for power tool OEMs and their final assembly operations.

Optimized manufacturing for a lower TCO

Our goal is to support OEM quality assurance and optimize the manufacturing process for a lower total cost of ownership. We provide the ISO-registered, documented QA you need for every phase of the mold lifespan:

- Design and development

- Prototype to production tool quantities

- Design maturation and optimization

- Operation

- Maintenance, repair and overhaul

Fast service and lower freight for Southeastern OEMs

Our headquarters in Easley, SC supports fast on-site service and lower freight costs for Southeastern manufacturers (we build and ship tooling coast to coast). Following installation, we extend the service life of your tooling with a dedicated maintenance operation that provides preventive maintenance, repairs and modifications to your molds (ours and tooling from other suppliers).

Total program management for

Die Casting and Metals Tooling

Total program management for

Plastic Injection Molding

Total program management for

Design and Engineering

To learn more about how JMMS can help you, call us at 864.855.0450 or email.