JMMS Tooling for

Returnable Packaging

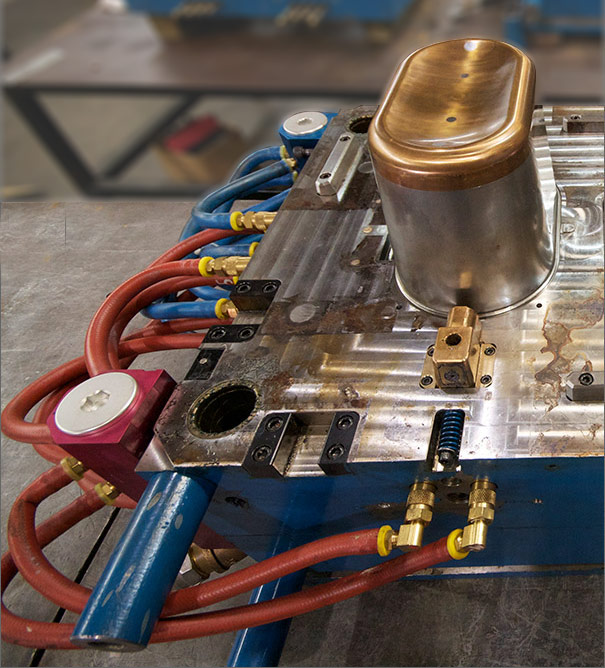

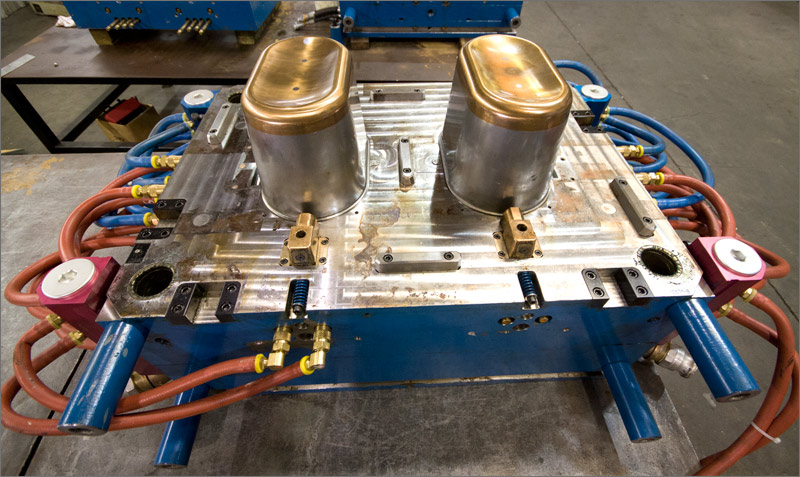

JMMS has extensive experience with improving supply chain management with tooling for returnable packaging. We design innovative frame and insert configurations, engineering multiple inserts that can be dropped into the molding machine frame, lowering cycle times and raising production capacity.

Tooling for returnable packaging:

- Automotive packaging

- Bread trays

- Composters

- Recycling bins

- Returnable pallets

The accountability and responsiveness of total program management

Our total program management begins with an assessment of your parts, packaging, materials and volume requirements. We can work with your production engineers and returnable packaging consultants to add strength and protection, while reducing weight and cost.

We’ll work with you side by side on-site, reviewing tryout data and optimizing your molds to use less material, cut cycle times and provide the component protection you need. Our primary objective is to help you optimize supply chain management, meeting customer QA while lowering the cost of ownership for your tooling.

We specialize in rapid prototyping and production of tooling for automotive packaging, bread trays, composters, recycling bins and returnable pallets.

Support for Southeastern OEMs and final assembly ops

We’re headquartered in Easley, SC with engineering and tool making operations in Dong Guan, China. Our South Carolina base positions us for fast on-site service and lower freight costs for Southeastern manufacturers (we build and ship tooling coast to coast).

JMMS provides ongoing service and support with our dedicated maintenance operation — preventive maintenance, repairs and modifications to our molds and tooling from other suppliers.

ISO-registered, documented QA for your molds

JMMS QA delivers the ISO-registered, documented compliance you need for every phase of the mold lifespan:

- Design and development

- Prototype to production tool quantities

- Design maturation and optimization

- Operation

- Maintenance, repair and overhaul

Total program management for

Die Casting and Metals Tooling

Total program management for

Plastic Injection Molding

Total program management for

Design and Engineering

To learn more about how JMMS can help you, call us at 864.855.0450 or email.