JMMS Plastics Tooling & Injection Molding

JMMS Injection Molding / Plastics Tooling

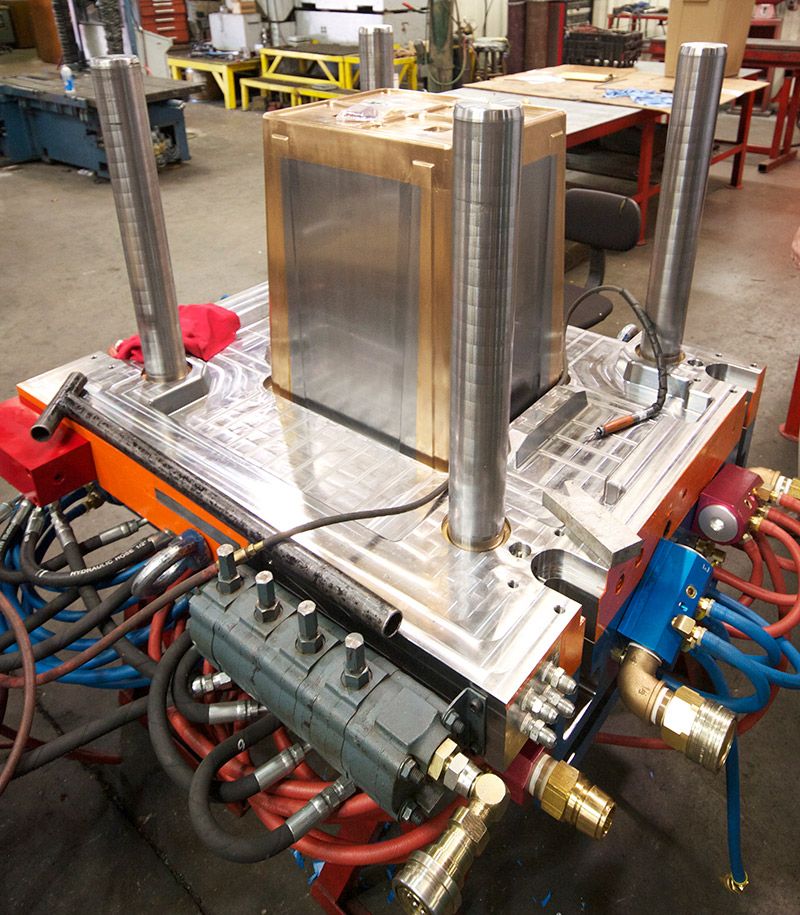

Our total program management for your injection mold tooling combines design support and assistance, rapid prototyping and concurrent engineering and lights-out manufacturing — plus maintenance, service and support.

Engineering OEM quality benchmarks into the mold

Our injection molding experience with global OEMs and their Tier base runs from minor parts to complex mechanical assemblies. We design, engineer and build molds up to 30,000 lbs., producing cores and cavities with speed and precision.

- JMMS engineers and tool makers have industry-specific experience with these injection molds, blow molds and transfer molds:

- Extrusion blow molding

- Thermoplastic injection molding

- Thermoset injection and compression/transfer molding

JMMS is cradle to grave on the Cimatron 13.0 platform, for building, modifications and service on molds up to 30,000 lbs.

Proven injection molding troubleshooting

Your QA demands complete control of the variables. Without it, there’s a long list of part problems that can delay or shut down productions. Read about what we do to prevent defects here.

JMMS delivers your molds as a package with 2D and 3D drawings.

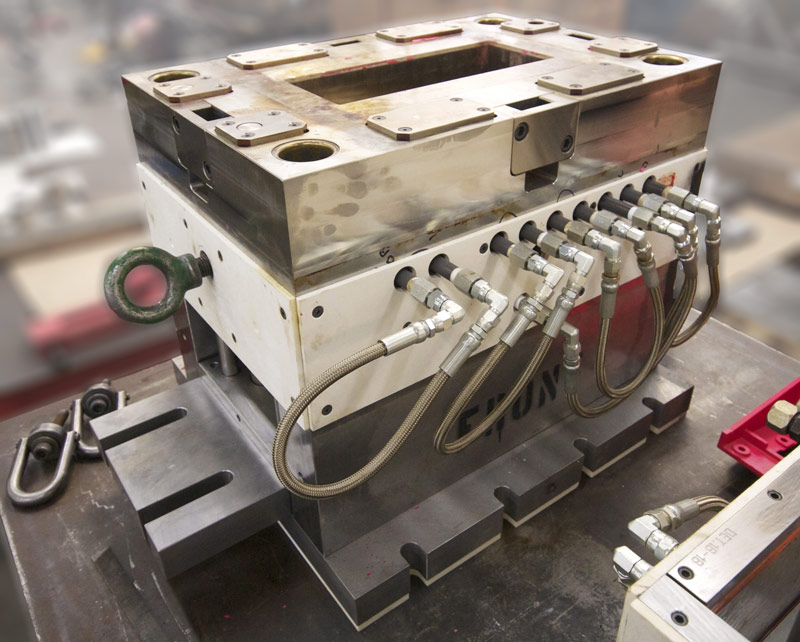

Turnkey mold packages

JMMS total program management integrates our industry-specific experience in an ISO-registered process, giving you a turnkey mold package ready for PPAP. We’ll work closely with your parts designers on part and mold optimization, to meet designer surface requirements for molds, in tooling that makes the specified part at the specified cycle time

The JMMS tag on the tool warrants the mold for appearance (design, workmanship and materials), cycle time and dimensional stability. We can warranty our molds for up to 1 million shots, depending on our history with the customer and a documented preventive maintenance program.

Total program management for Injection Molding & Plastics Tooling:

To learn more about how JMMS can help you, call us at 864.855.0450 or email.