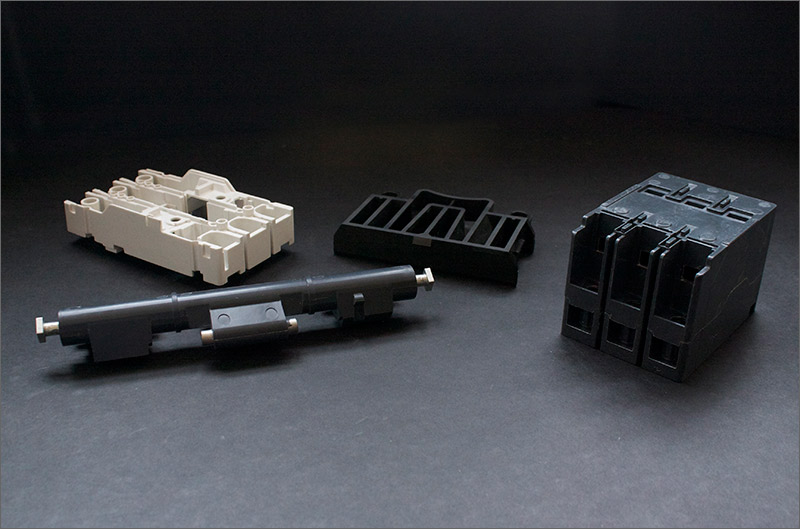

Thermoset Injection & Compression/Transfer Molds

We offer total program management for thermoset injection & compression/transfer molds, including design and engineering, manufacturing and maintenance. Our industry-specific experience includes building thermoset injection molds for electronics and power generation OEMs.

These molds produce a range of durable, cost-competitive parts, including electrical switches, covers and 400-amp breakers. Our engineers focus on both part and mold optimization, to reduce material usage and cycle times while meeting OEM quality benchmarks and production volumes.

Industry-specific thermoset injection & compression/transfer molds for:

- OEM electronics

- Electric meters

- Gas meter housings

- Thermoset breakers, busway and arc shields

- Transportation

- Insulators for third rails

- Power generation

- Thermoset insulators

- Thermoset breaker housings

- Thermoset throw switches

- Thermoset armatures

JMMS has extensive experience with hard-chrome plating H13 hardened steel, to handle the abrasives in thermoset plastics.

Experience with hardened tool steels

JMMS engineers have extensive experience with manufacturing thermoset injection molds robust enough to handle the abrasives in thermoset plastics. We use H13 hardened steel for our mold cavities, hard-chrome plating them to withstand wear.

We warranty these molds for appearance (design, workmanship and materials), cycle time and dimensional stability. Depending on our history with the customer and a documented history of preventive maintenance, we can warranty our molds for a given number of cycles.

For more information, contact Brian Rossi at 864.855.0450.

Total program management for Injection Molding & Plastics Tooling:

To learn more about how JMMS can help you, call us at 864.855.0450 or email.