JMMS Information for Purchasing Agents

We meet the most stringent due diligence requirements for tooling suppliers. JMMS has the financial strength and capital resources to invest in business growth, while meeting the commercial terms of the world’s leading OEMs and their Tier vendors.

Here’s an overview of our business case:

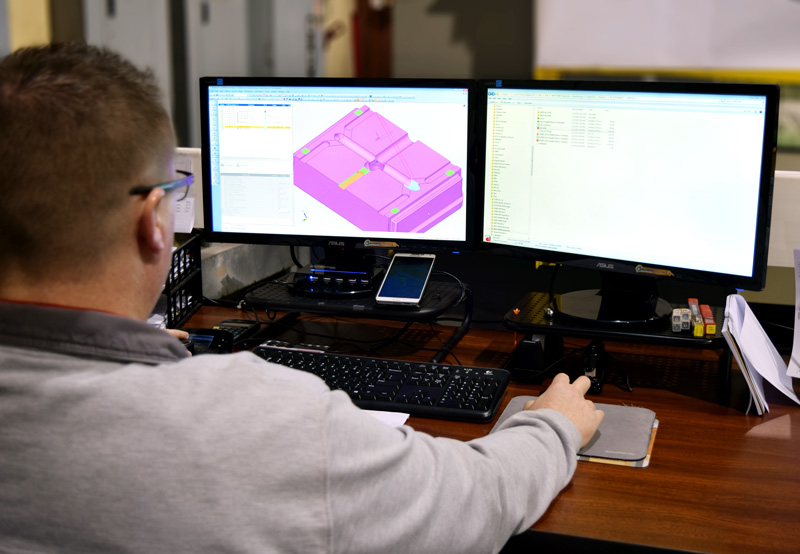

Full-service metal working capabilities

- Our die & mold total program management includes design and engineering, manufacturing and maintenance for single-source efficiencies.

Competitive pricing

- Mature, proven in-house tooling design, engineering and manufacturing, backed by the competitive baseline pricing of our Asian tool making operations.

Faster lead times

- Concurrent engineering integrated with Lean principles and lights-out manufacturing for faster development and production.

Relevant industry experience

- We have longstanding OEM relationships based on project management, problem solving, and process improvement.

ISO certification

- The documented QA your engineers want, with a mature, ISO-certified continuous improvement process.

JMMS Management Team:

- David M. Bowers, President

- David M. Bowers II, Chief Executive Officer

- Michelle Powell, Chief Operating Officer

- David Walker, Engineering Manager

- Brian Rossi, Project Manager - Thermoset

- Kevin McConnell, Project Manager - Die Casting

- Jeramy Martin, Project Manager - Plastic Injection

- Jennie Boyle, Quality Assurance Manager

- Ahai Yuan, Asia Business Manager

Brochures & Datasheets:

JMMS Locations:

Our conservative business management and financial strength support ongoing relationships with leading global OEMs and their supplier base.

We make ongoing investments in our QMS and ISO-certified continuous improvement.

To learn more about how JMMS can help you, call us at 864.855.0450 or email.