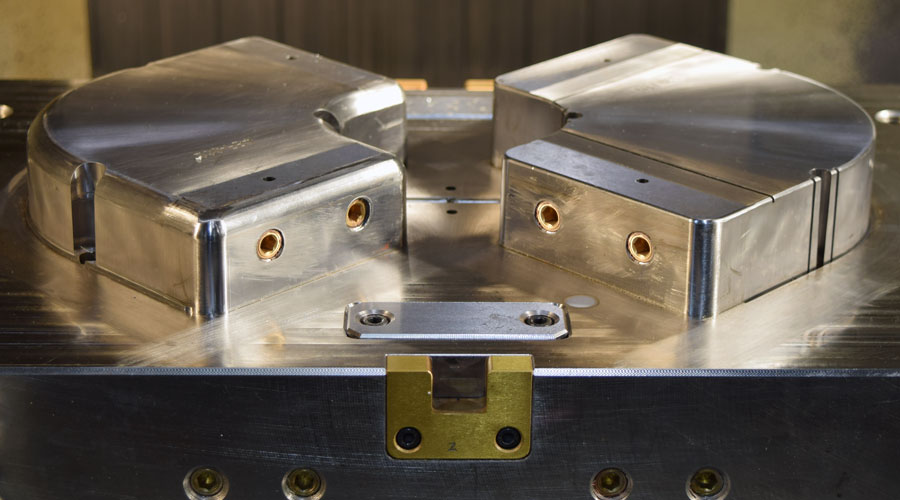

Die & Mold Total Program Management for OEMs and Tier Vendors

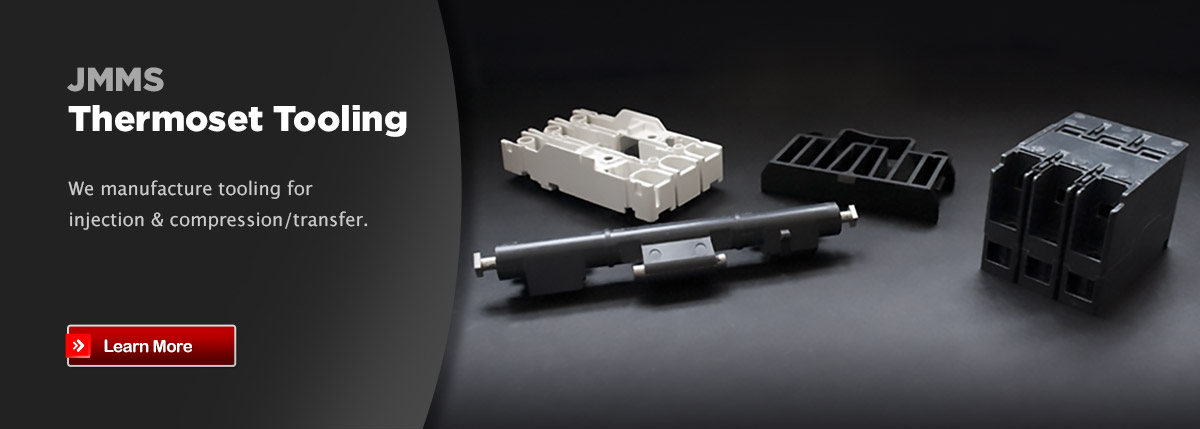

We deliver total program management for thermoplastic injection molding, thermoset injection & compression/transfer, and die casting tooling. Our work supports the quality benchmarks and production schedules of the world’s leading OEMs and Tier vendors.

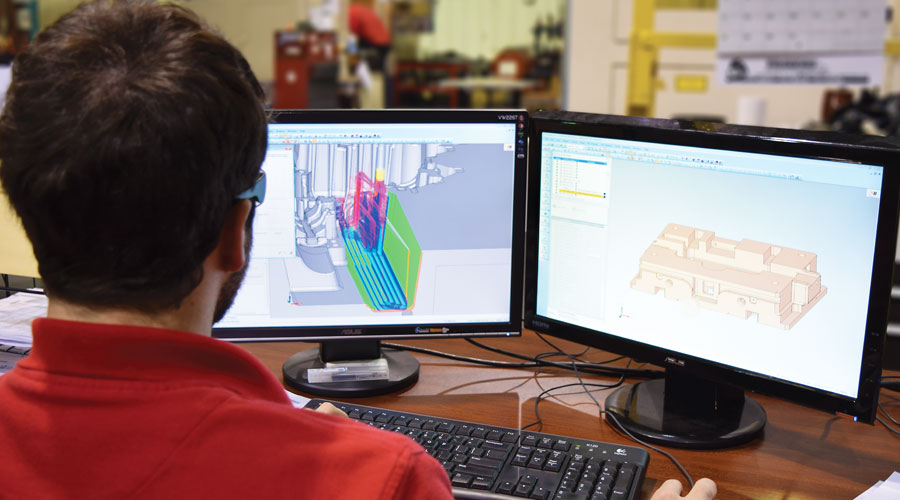

JMMS engineering can help you improve part quality, use less material and lower cycle times for better manufacturability. We do this with dedicated project managers, design validation and concurrent engineering, for the shorter lead times OEMs require.

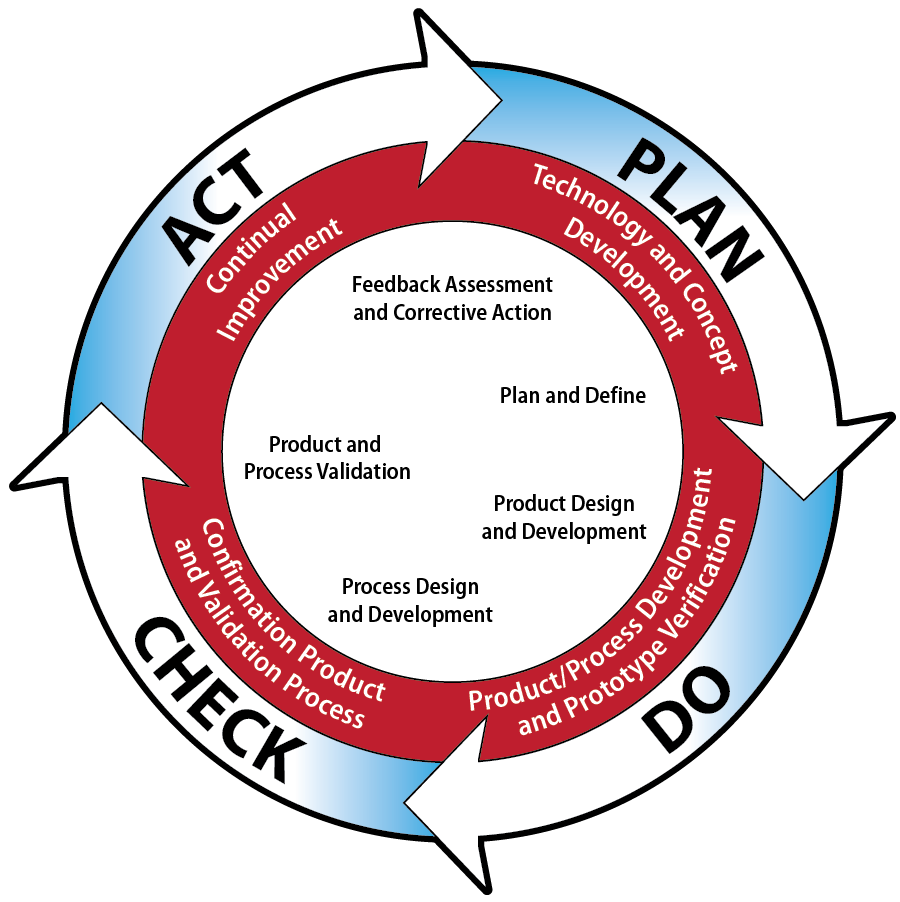

Advanced product quality planning (APQP) guidelines

drive JMMS design, engineering and manufacturing.

Interested in total program management for your die cast and injection molding/plastics tooling?

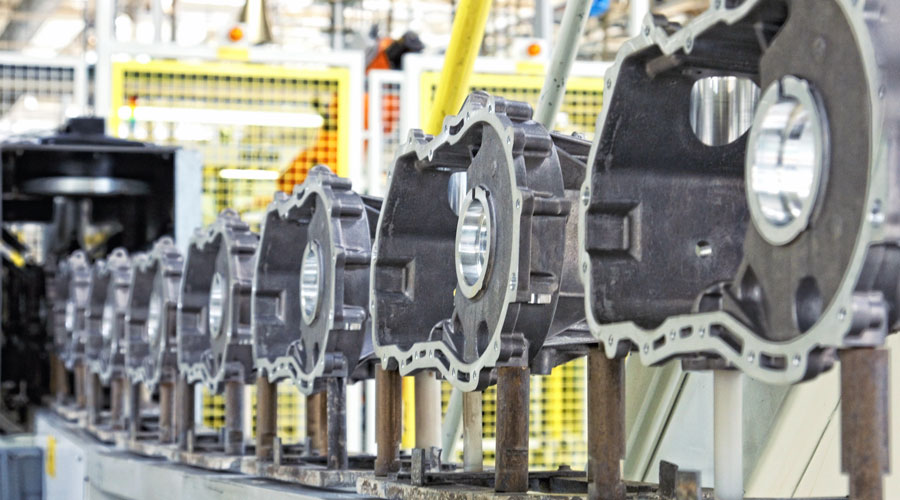

Don't let parts slow or shut down production

Problems with part quality or cycle times? We can help. As a Tier One vendor, JMMS works with OEMs and other Tier vendors on tooling engineering to reduce scrap and secondary operations with shorter cycle times.

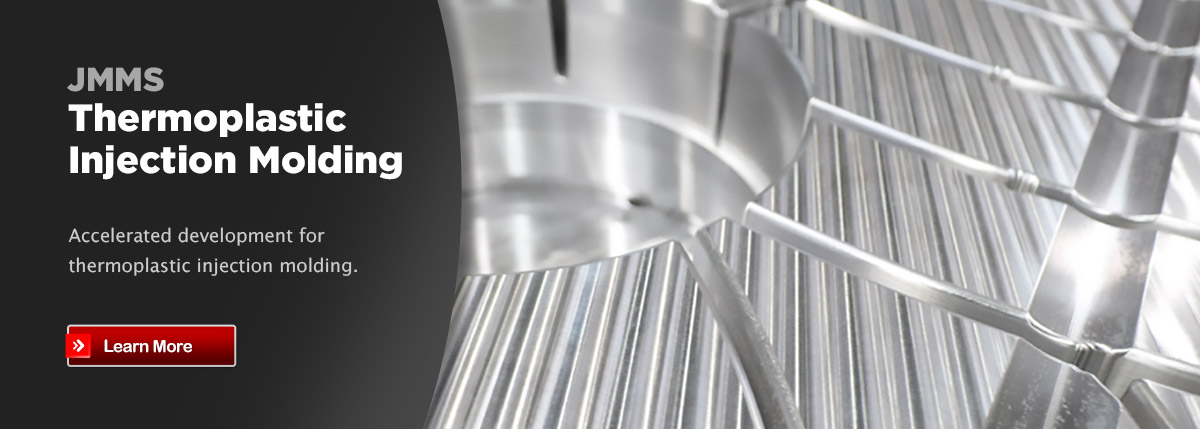

Injection molding troubleshooting for consistent parts

JMMS engineers know how to design injection molding tooling that delivers the specified part quality and cycle times. We review and assess your production issues to make mold and process recommendations.

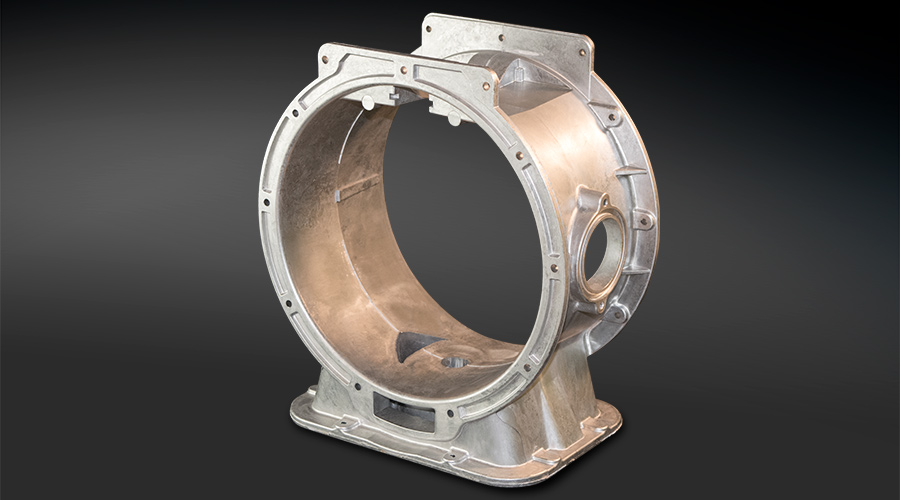

Reduce or eliminate secondary operations on die cast parts

JMMS engineers develop die cast tooling to produce parts in at or near net shape, reducing or eliminating costly secondary operations. We also correct venting and temperature control problems to reduce porosity in parts.

JMMS total program management accountability

OEMs refer JMMS to their Tier vendors because we solve production and quality problems. Our total program management includes design, engineering, manufacturing and maintenance for single-source accountability.

About JMMS

Next generation tooling gives you a standardized, consistent, repeatable process — to meet OEM quality benchmarks and lead times, with a lower total cost of ownership. It combines a tradition of metalworking craftsmanship with a commitment to continuous improvement in engineering, manufacturing and service.