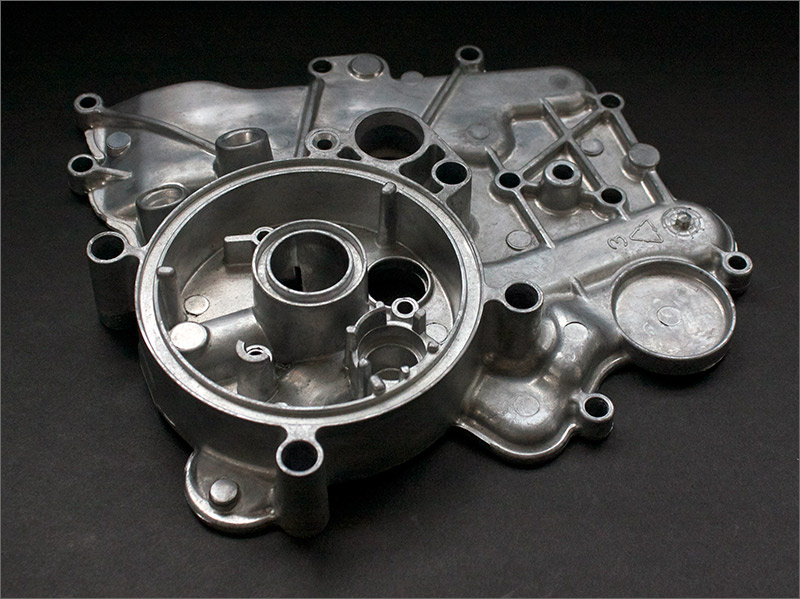

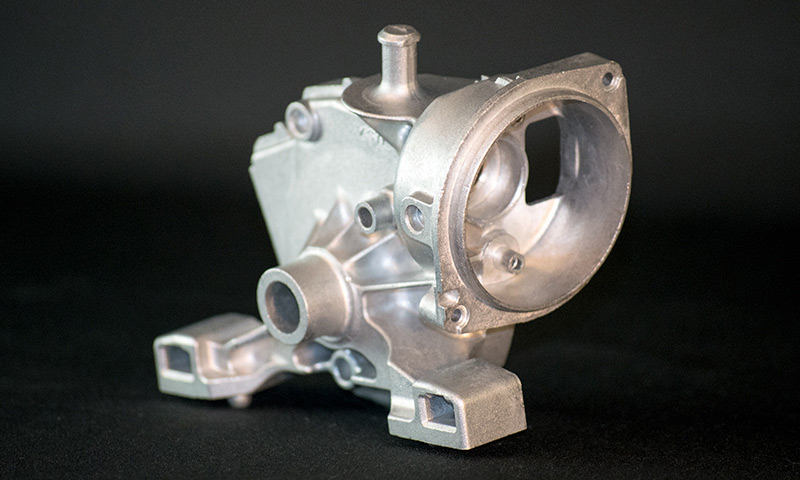

We offer total program management for low-pressure casting dies, including design and engineering, manufacturing and maintenance. Our experience includes tooling for automotive OEMs and Tier vendors producing brake and suspension components.

- Automotive OEMs and Tier One vendors

- Brake components

- Suspension components

A focus on better part quality and manufacturing

JMMS engineers specialize in part and die optimization, to meet OEM specifications while reducing cycle times, material usage and secondary operations. We can reduce wall thicknesses to minimize fill and cooling times, add radial corner designs to minimize stress concentrations and fractures, and draft angles for easier part removal from the die.

Our concurrent engineering, rapid prototyping and global tool making resources accelerate die development and production, giving your engineers the time to focus on maturation and optimization.

JMMS works with automotive OEMs and Tier One vendors on low-pressure casting dies for small and medium-sized alloy parts.

An ideal partner for long or short production runs

We have the prototyping experience you need, with design validation and concurrent engineering. JMMS low-pressure casting dies are warrantied for appearance (design, workmanship and materials), cycle time and dimensional stability.

Total program management for die casting and metals tooling

- Die cast design and engineering

- Part design/assistance

- Dedicated Project Management

- Concurrent engineering/rapid prototyping

- Die cast maintenance and repair

- Preventive service, repairs and modifications

- On-site support for plant maintenance

- Pickup and delivery

- In-house welding and stress relief

- Quick-turn scheduled service for minimal downtime

Die cast total program management for OEMs and Tier vendors

To learn more about how JMMS can help you, call us at 864.855.0450 or email.