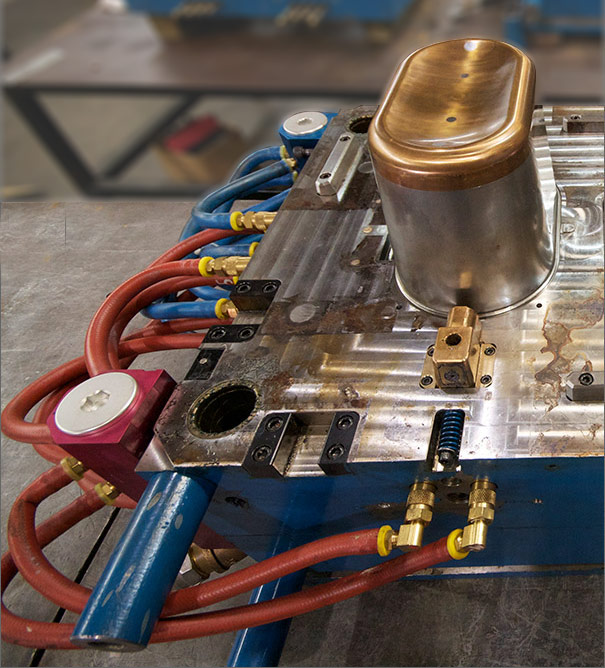

JMMS Low-Pressure Injection Structural Foam Molds

We offer total program management for low-pressure injection structural foam molds, including design and engineering, manufacturing and maintenance. Our experience includes tooling for returnable packaging OEMs and material handling applications.

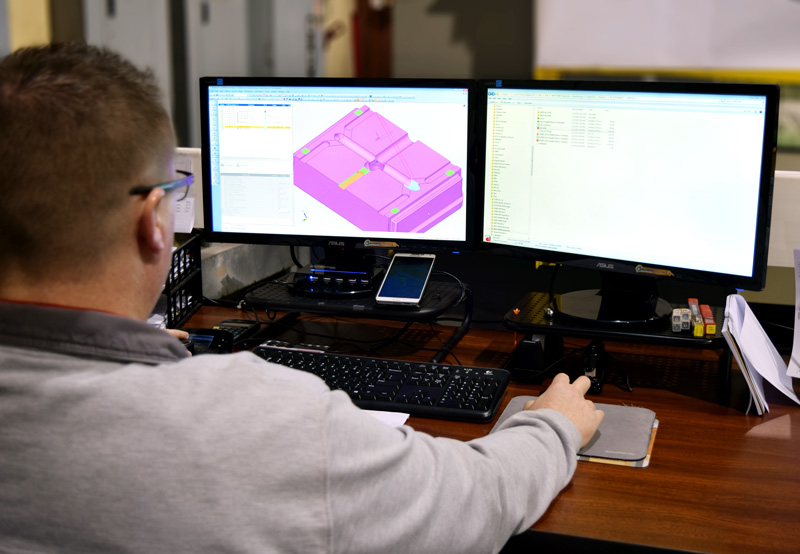

Part and mold optimization

JMMS engineers work with your production engineers on part and mold optimization. Our objective are to reduce material usage by redesigning thick wall sections for runners and channels, and reducing cycle times with innovative frame and insert configurations. These inserts can be dropped into the molding machine frame to cut cycle times and increase production capacity.

All JMMS structural foam injection molds are warrantied for appearance (design, workmanship and materials), cycle time and dimensional stability.

Low-pressure structural foam injection molds for:

- Consumer products

- Shelf bins

- Delivery trays

- Convenience store shelving

- Child safety seats

- Returnable Packaging

- Automotive packaging

- Bread trays

- Recycling bins

- Composters

- Collapsible pallets

- Returnable pallets

JMMS engineers use tool-grade aluminum to make molds for returnable packaging OEMs and material handling applications.

Total program management for Injection Molding & Plastics Tooling:

To learn more about how JMMS can help you, call us at 864.855.0450 or email.